Contributed By Greg Fonts

Let’s face it if you don’t have a roller gun, you probably have looked at one or know someone that has one. If you have ever tried one and it was a disappointment chances are it was rigged improperly or the roller head was just not designed properly. I received a text from a friend the other day showing this bad ass roller from Europe he had just purchased, what he failed to look at was the actual roller parts of the gun. The gun was beautiful, the rollers on the other hand were a joke, and at the end of it all the gun shot like crap.

When it comes to rollers, you generally will encounter two types bushings aka plain bearings, and bearings. Bushing generally are made of some form of PTFE aka Polytetrafluoroethylene or Acetal. These materials are generally highly hydrophobic, meaning neither water nor water-containing substances wet it, PTFE being the most hydrophobic between the two. Acetal does tend to have a much higher tensile strength. Either way, in the test we have run we see a 10 -15% reduction of performance when bushing where compared against high quality bearings.

Now if you talk to companies that push bushings they will say “ the advantage gained from roller bearing are not significant, and there are several disadvantages. The two main disadvantages are cost and durability.” Point one is correct bushing are way more cost effective than good bearings, and that is why you will see the more cost effective roller muzzles with bushings. Now bearing durability has to do with the materials used, most either use stainless steel, glass, or ceramic.

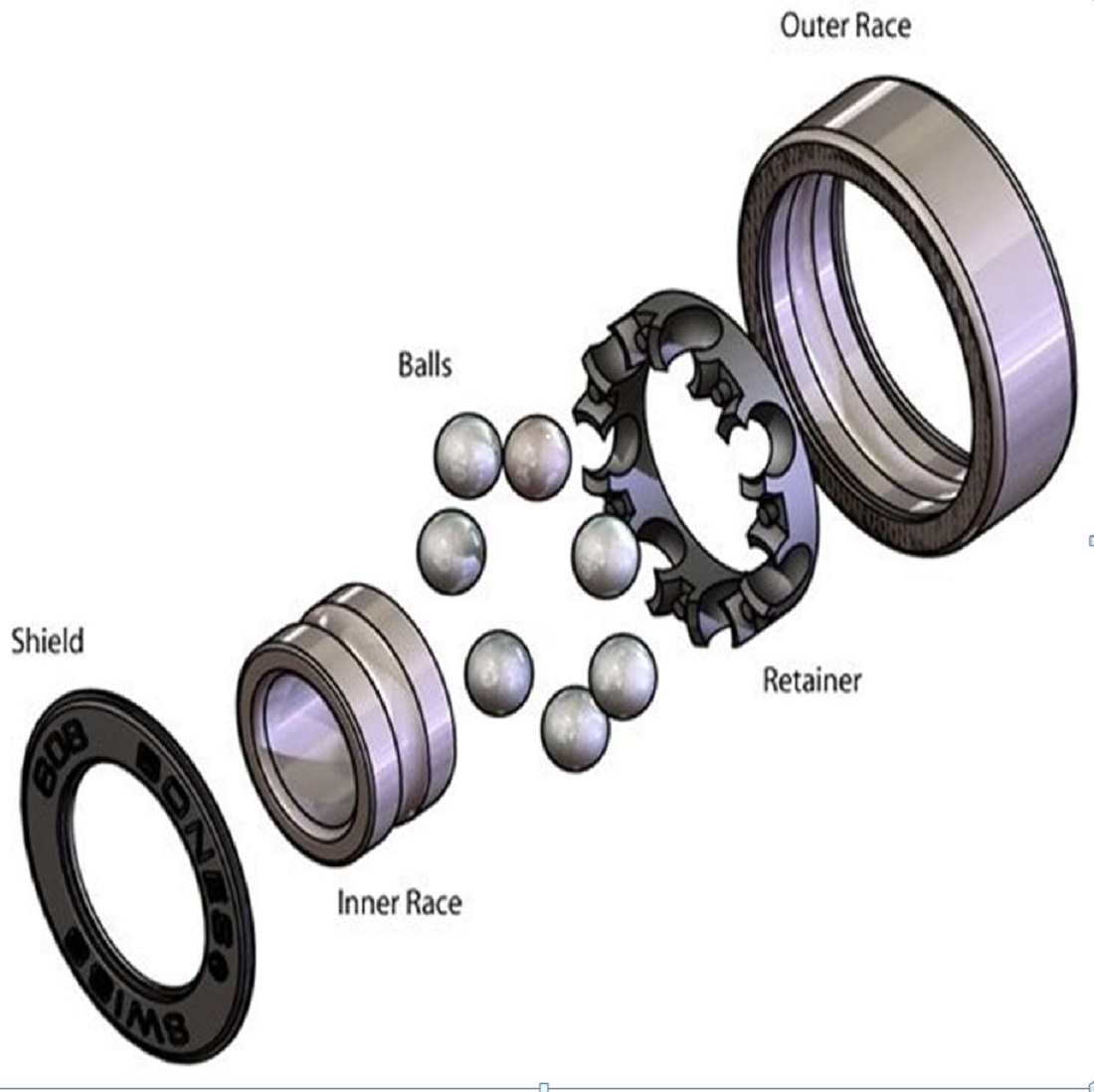

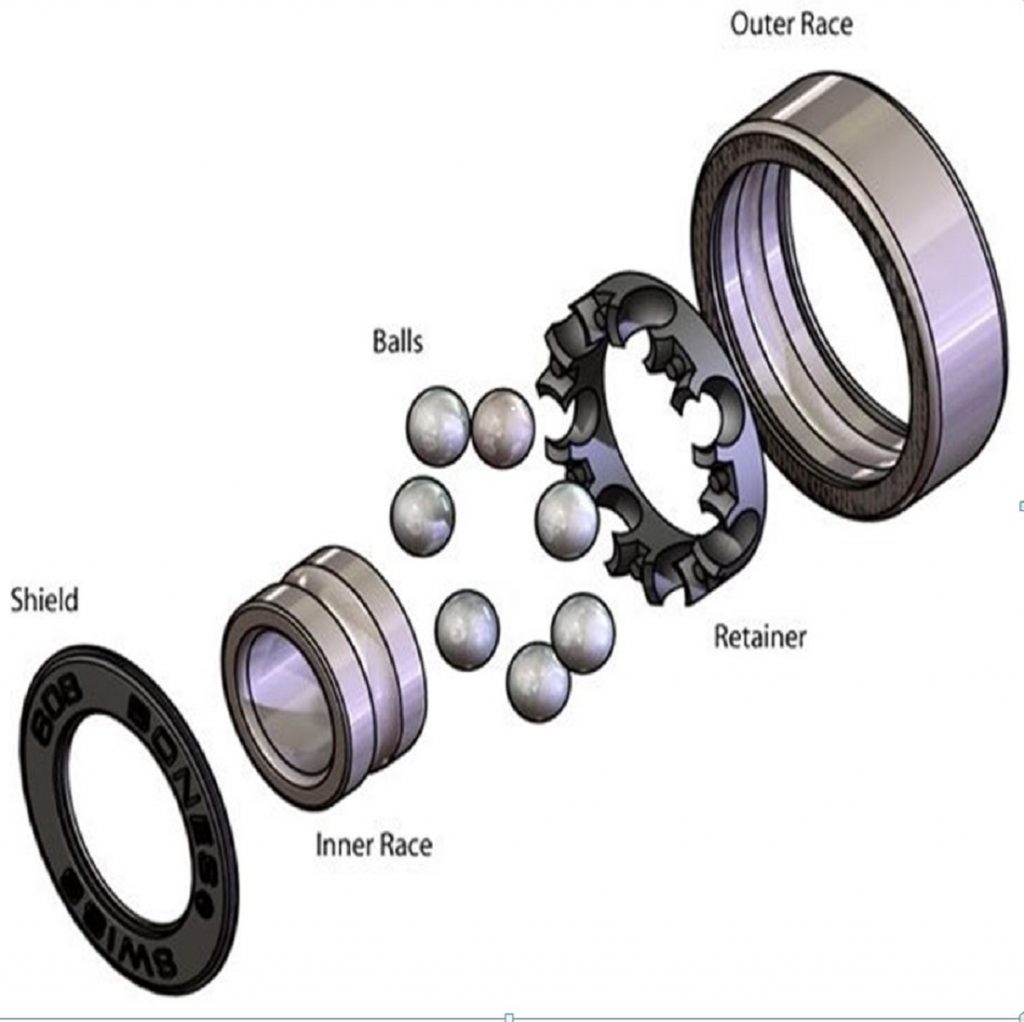

With a bearing roller muzzle using a total of 4 bearings the effect of various materials can determine performance. Let’s break down what comprises a ball bearing,

Inner and outer race: Each race is a ring with a groove where the balls rest. This can also define the bearing as a hybrid bearing which consist of a race material differing from the bearing material. A standard bearing would consist of the bearing and races being the same material.

Balls: Generally made from SS, Ceramic, glass, or plastic. Each material has it applications and uses, but the most common in roller muzzles are glass or ceramic. Glass are mostly used and the most affordable, Ceramic bearing muzzles will be much more expensive and less prone to grit and sand damage.

A few facts on ceramic bearings:

- Ceramic bearings are mostly made using ceramic silicon nitride (Si3N4) which is both lighter and harder than traditional steel bearing

- Thanks to silicon nitride being less dense than steel, the bearings are up to a third lighter than comparable components made from steel.

- There are two types ceramic bearings—hybrid ceramic bearings and full ceramic bearings

- Because ceramic bearings are harder than steel bearings, they are more durable, lasting anywhere from five to 20 times longer. Also allows for crushing of less dense materials like sand.

Shroud: Most Roller muzzles will not include a shroud as it allow for the flushing of the bearing after use.

Now that you know a little about the materials and options we are going to throw one more wrench in the equation. Within all these material are different ratings. So yes you can have a nice light full ceramic bearing with horrible specs, and a not so expensive glass ball bearing with higher specs that performs very well.

Our friends over at F1 Ceramic Speed Upgrades have done a great job at breaking down the differences:

“Bearings are rated in two distinct ways: Ball Grade and ABEC.

Ball Grade (Lower is better)

Ball grade is a rating of the individual ceramic balls. The ball grade is a measurement of the roundness (how perfect) of the ball. This is the single most important rating of a bearing. If you buy a bearing based on 1 rating or spec, ball grade would be it. Race quality and retainer type would follow that in terms of what impacts the speed of a bearing.

Balls are graded as follows:

Steel: Grade 300, Grade 100, Grade 25 , Grade 10 (Grade 10 is the best quality steel ball we have found)

Ceramic: Grade 10, Grade 5 & Grade 3.

The lower the number, the better quality ball.

For example premium grade 3 balls. This means the ball is round to 3 millionths of an inch. Most steel bearings use balls that are grade 25 and more often even worse.

For arguments sake, say you had a grade 3 steel ball (even though they don’t make them that high of a grade) and a grade 3 ceramic ball. While similarly round, the ceramic still has the edge in hardness and durability. The ceramic ball will not deform, rust, flat-spot, crack, wear out and most importantly, will not create heat (friction, very bad!). The steel ball will! Not to mention the ceramic ball will clean the bearing race with use, making the bearing faster and much more durable!

ABEC (Higher is better)

The purpose of the ABEC committee (Annular Bearing Engineers Committee) is to establish dimensions, tolerances, geometry, and noise standards for bearings in an attempt to aid industrial bearing manufacturers and users in the production, comparison and selection of bearings.

ABEC is often misunderstood and thought to be the “defining” rating in a bearing. ABEC simply refers to the overall tolerance of the bearing. Tolerances control the dimensional accuracy of the bearing. This rating is useful for industries where high RPMs (10,000 or more) are used such as machinery.

A better ABEC rating does not impact the speed of the bearing.

On the same note, some bicycle bearing manufacturers market ABEC 7/9 bearings as their main selling point. While the ABEC 7/9 tolerance is tighter than an ABEC 5 rated bearing, the speed of the bearing will not be any faster.

In terms of cost, there is no difference between the ABEC tolerances in manufacturing.

ABEC rates the overall tolerance of the bearing. ABEC does not rate speed or how fast a bearing is.

Bearings are ABEC rated as follows:

ABEC 1, ABEC 3, ABEC 5, ABEC 7 & ABEC 9 (tightest tolerance)

The higher the ABEC rating, the tighter the tolerance of the bearing.

But remember tolerance does not effect the speed of the bearing for certain applications. It is used so that manufactures can match the tolerance needed for their product (machinery, tools, etc.) A piece of machinery spinning at 10,000+ RPMs would require a high ABEC rating, such as ABEC 9.

By no means are we bearing experts, but we have done some homework and testing, please use this article as a starting point. Thinking of what makes up a roller gun is important, bearings and bushing being really one of the most important parts.. The next time you are looking at roller don’t just look at the exterior, look what’s in it!