Contributed by Greg Fonts

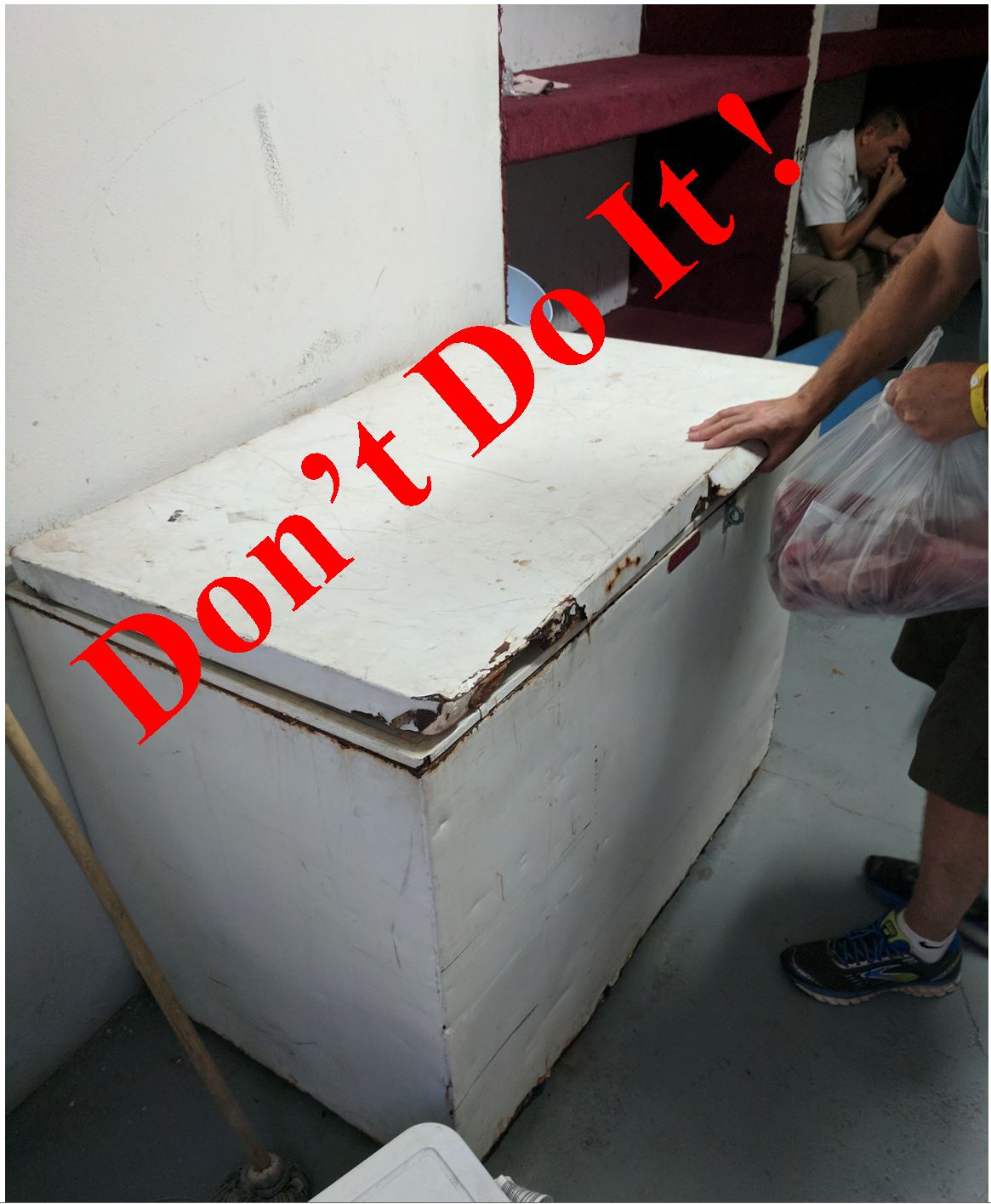

At some point in a galaxy far far away someone came up with the genius idea of preserving their spearguns rubber in the freezer, it works for meat and fish so why not rubber. That person then took it upon themselves to go on every spearfishing forum including the Freedive List ( Freedive List was the first freedive and spearfishing forum dating back to the late 90’s) and spread the idea which is still being passed on today. If you are suddenly finding yourself looking in the mirror it is not too late to stop the madness.

All high quality speargun rubber is made of natural latex rubber and manufactured by a dipping process, not extruded like pretty much all rubber coming from China and surrounding countries. This manufacturing process involves a considerable amount of water, and because of this rubber coming from the factory is not completely cured and still contains moisture. Over the next one to two months the rubber will continue to cure and dry out, it is at this point that most consider the rubber to be at its best. If you freeze or even refrigerate your rubber during this stage the curing process can be affected, as well as you risk turning the moisture into ice crystals creating micro tears in the rubber.

Besides the points listed above there are three other factors that damage rubber in storage and in use:

Heat: While speargun rubber is flexible at 0 Fahrenheit and can perform in temperatures as high as 158 F continuously, it is recommended that that you store your rubber at room temperature somewhere between 50 to 80 degrees F. Speargun rubber is a vulcanized product so the rubber actually will continue to cure throughout its life slowly becoming stiffer.

Ozone: In basic terms Ozone is gas produced by sparks/arcs between the brushes and the commutator in Electric motors, ozone is also produced by electric transformers. Both refrigerators and freezers have electric motors which produce ozone, as well as other electrical machinery or electrical panels. Primeline actually adds a small amount of wax to their compound which is a anti-ozoneant, this is why the first time you pull your bands back you may get a white film on your rubber. It is the wax working its way to the surface as the rubbers cures, see the band below after initial stretch.

UV: UV break down is hard to avoid, a good thing is that most manufacturers are producing rubber with a colored outer layer which help protect from this. In the speargun rubber world the pure “amber” colored rubber is what actually has the most potential energy, the outer colored ring is what help with the UV rays. The use of band socks or covers can really make a difference over the life of the band.

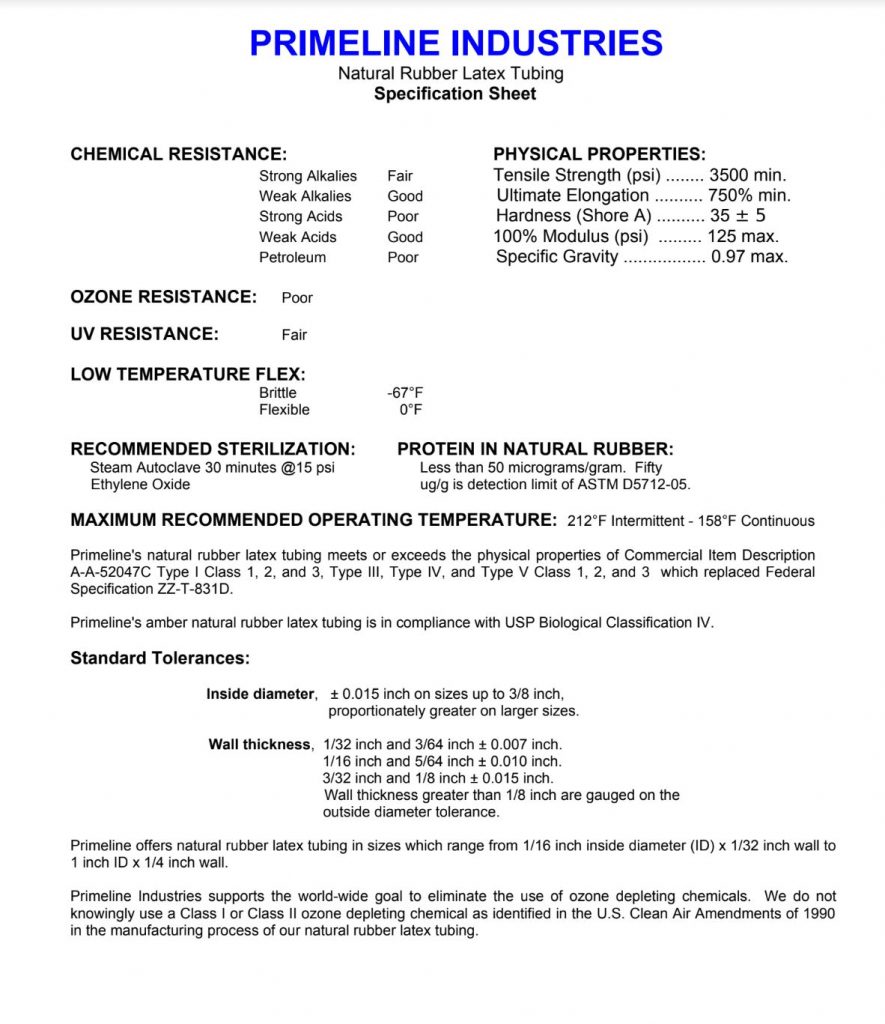

Below you can see the chemical spec sheet from Primeline, the producer of what is considered the best speargun rubber on the market. Take notice of the the chemical resistance and please do not use any petroleum lubricants to insert your wishbones.

So if you are wondering how to store your rubbers here is what the manufacturer recommends:

Primeline certifies that the shelf life of our natural rubber latex tubing is indefinite when

stored properly.

Recommended storage: Storage should be in such a way that the tubing is protected from

high temperatures, UV light, and ozone. In normal room temperatures 50 to 80 degrees

F., in a closed box or carton, and away from UV light and ozone generating devices such

as electrical motors, and electrical transformers.

So if you have any rubber in your freezer right now please go save it!