Foam Filling Handles

Contributed by Greg Fonts

As guns get shorter their ability to float decreases, especially if adding a reel. We pretty much exclusively hunt Rob Allen Spearguns and when you get a RA Tuna in the 70cm range, the gun becomes negatively buoyant when the spear is out. Lighter tubed guns such as the RA Scorpia do not have this issue as they have a thinner walled barrel.

We have also used this on guns that are “ass heavy” meaning when the gun is floating on the surface the muzzle is the only visible part. Adding foam helps the handle float making the gun more visible in the water.

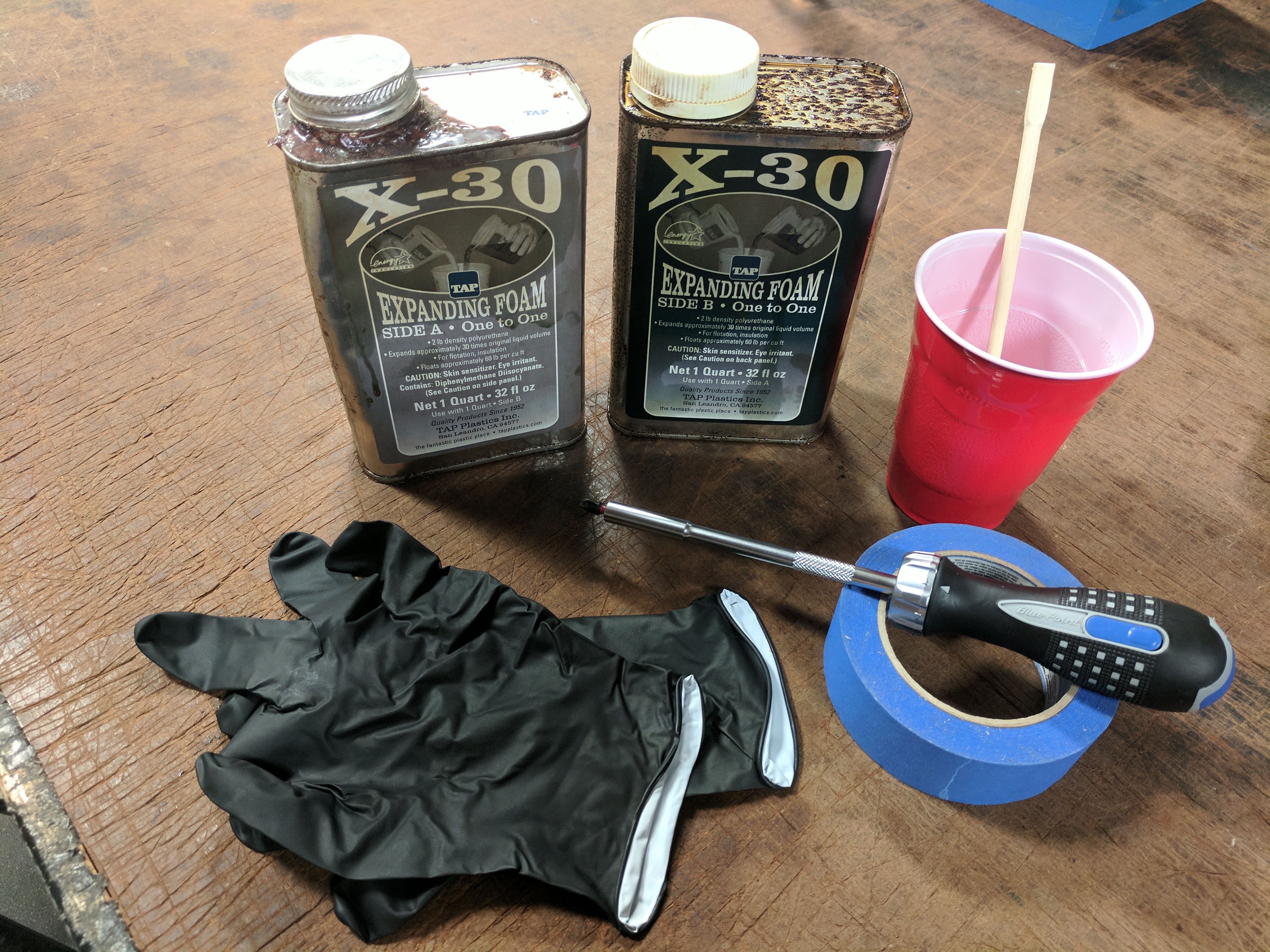

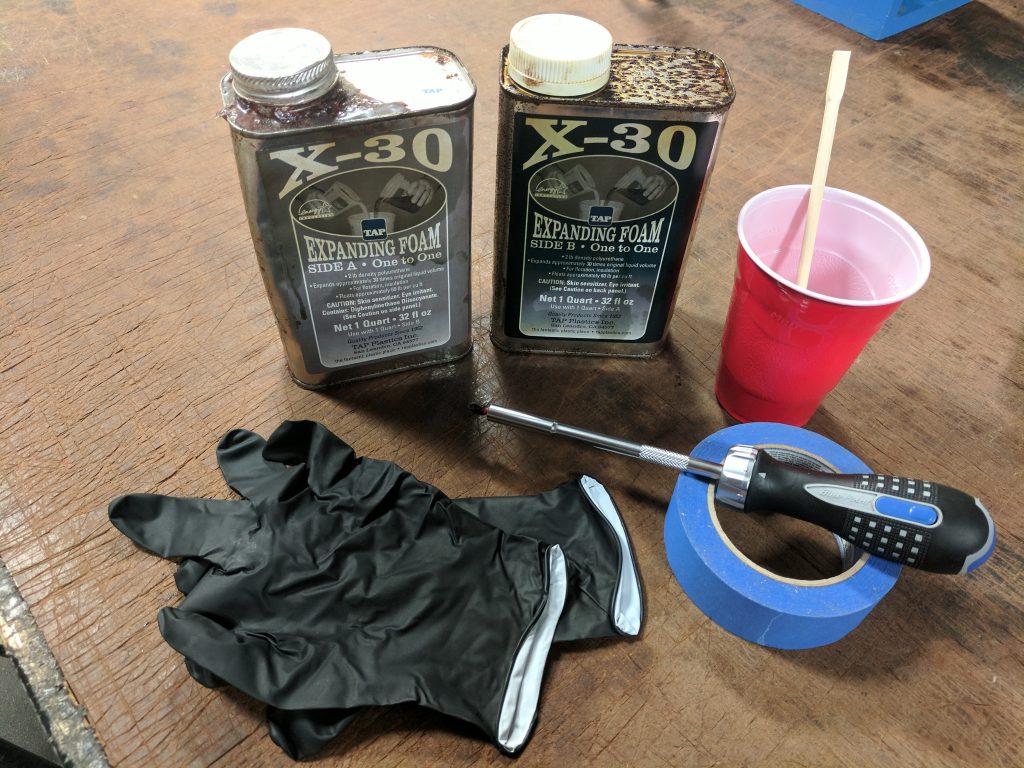

What Necessary:

We use X-30 foam from Tap Plastics, it is available in a few different quantities. A extremely minimal amount is needed, we uses about 1 Teaspoon per part to fill 1 handle. Also, use gloves as this stuff is rather sticky, and like 2 part epoxy get a little warm as it cures.

Step 1:

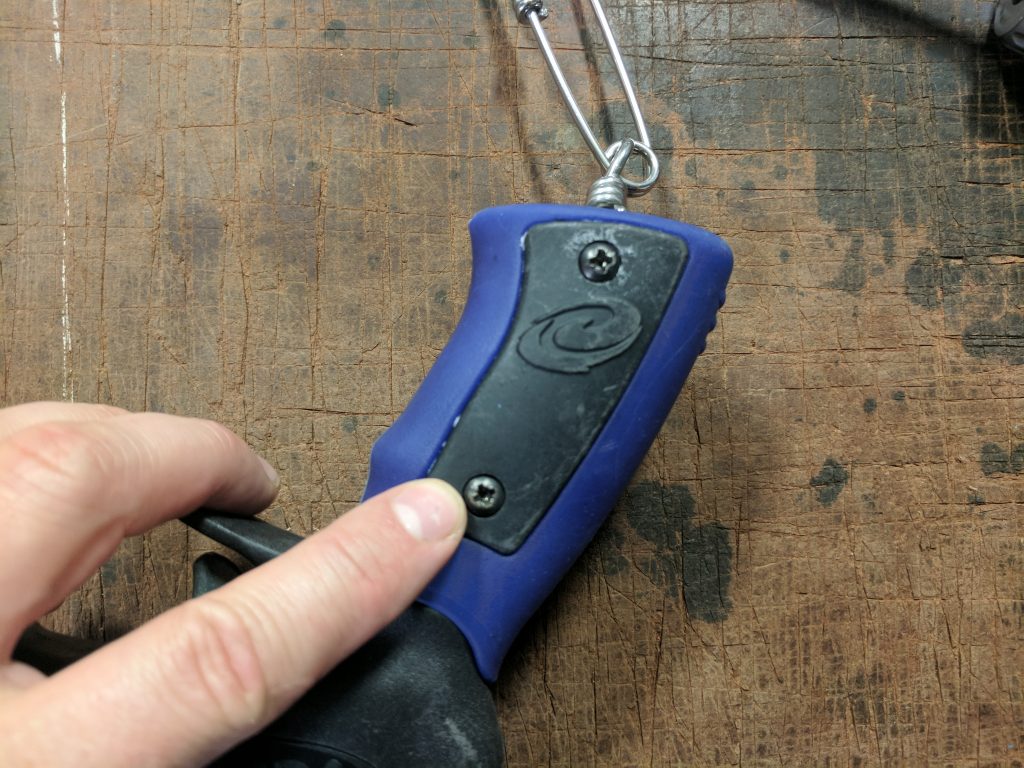

On a Rob Allen there is a void in the handle that is independent of the mechanism. If you are doing this to another brand gun make sure the void you are filling is not going to impact the mechanism or drain holes. Remove side screws, the longer is on the bottom of the handle. Pry off Side plates.

Make sure to unscrew side plates with the actual screw heads, one plate has false screw heads.

Step 2:

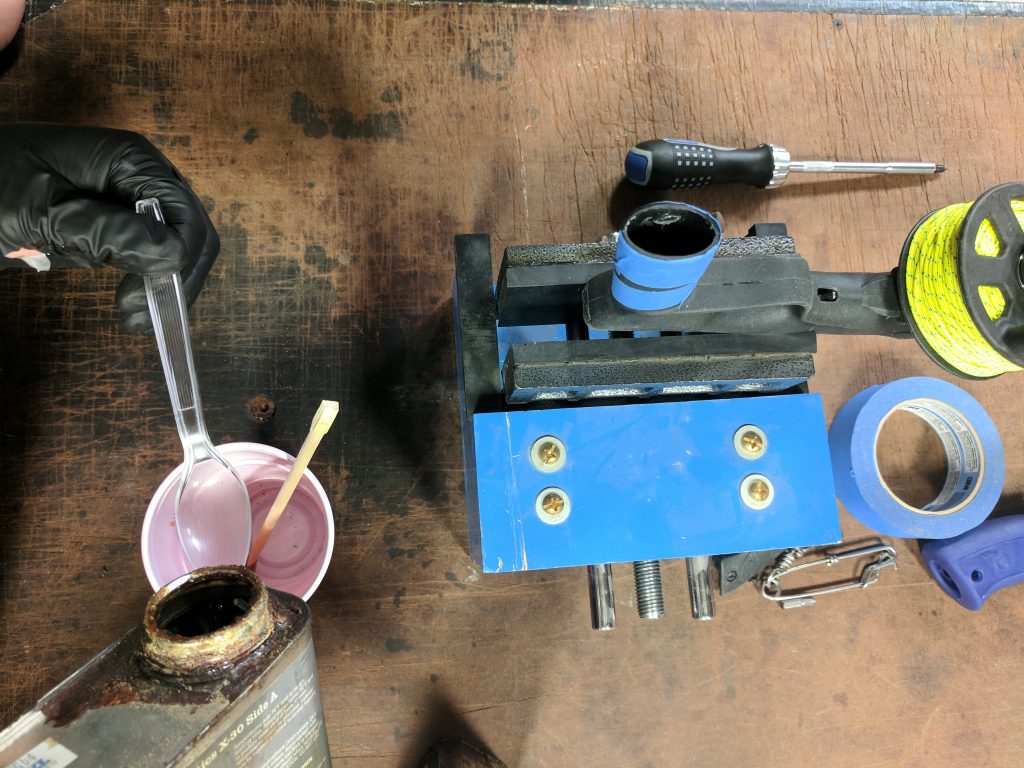

Tape up any holes with easy to remove tape such a blue painters tape. You can also tape surrounding handle to protect it from overflowing foam.

Step 3:

Secure the gun in some sort of vise. Get mixing container and mixing device, we use a chopstick. Whatever you use for mixing container plan on disposing of it if you do not immediately clean out. As mentioned above this stuff can get hot so be careful.

This foam is a 1:1 part A/B mix. We use approximately 1 Teaspoon of each part which expands to more than what we need. If you would like to plan the amount the foam expansion rate is approximately 30x original liquid amount if mixed thoroughly. . Pour measure amount in to mixing container and start immediately mixing., it is ready to pour when it takes on a tan like color. Puur into void and wait for the expansion.

Let foam cure for approximately 20 minutes until firm to the touch.

Step 4:

Now that the foam is hard you wan trim and shape with a sharp knife. We cut our flush with the handle.

An additional step is to make a slice into the foam to make inserting the tuna clip back into place. To lighten the gun even more we are replacing the clip with a mono loop.

You can now remove the tape, slide the handle cover back on, and insert clips or mono loop.

Step 5:

Reassemble side plates and screws. To make it easier you can drill out the screw holes. Make sure you replace the screws in the correct order, in this case longer screw on the bottom.

If you have any questions or comments please contacts us at UltimateSpearfishingMedia@gmail.com. We have heaps of this stuff so stop on buy, bring your own containers ?.